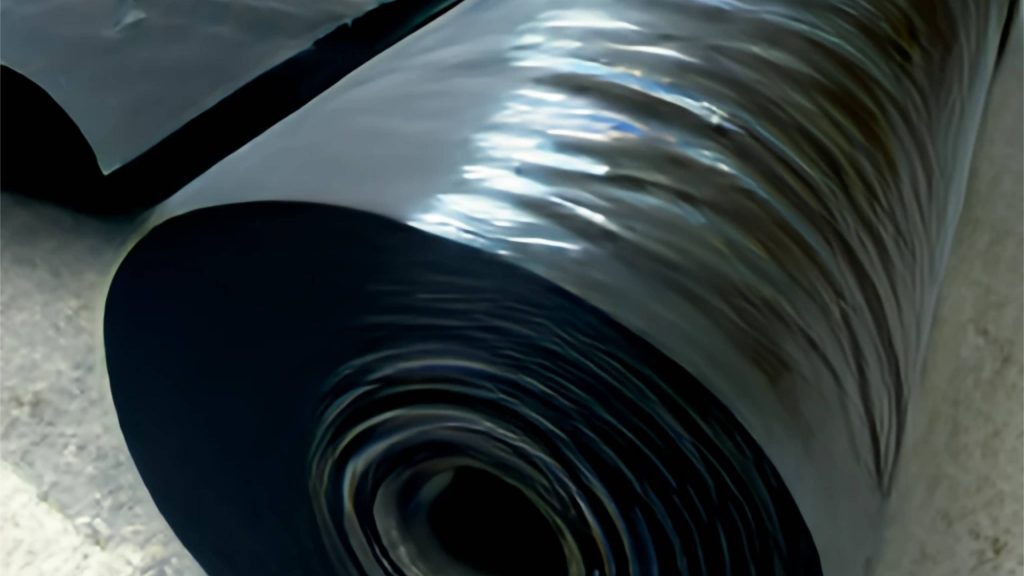

Black polythene isn’t just for bin bags, you know. This super versatile material has found use in everything from construction to farming. In fact, the food you eat was probably grown in black polythene bags. It’s one of the most important materials in the world as a result, with a high demand in a range of sectors.

But it’s far from a simple substance; black polythene has been engineered over the decades into a high performance material for the applications it serves. Makers have developed custom polymer blends, masterbatches and additives, that achieve unique properties.

Black polythene may be exposed to strong UV light, which can break polythene down and make it brittle. Standard polythene bags might not always have the right opacity at lower gauges. And certain duties of polythene may not have the strength to achieve the rigorous standards of modern construction practices.

So, let’s learn more about black polythene, and the uses it has in the world.

Practical uses for black polythene

Black is easily one of the most useful and popular colours in the world – but it has practical uses due to the way it absorbs different kinds of light. This is particularly important in construction.

Black polythene sheet for construction

Heavy duty polythene for construction is used for loads of purposes;

- Damp-proof membranes

- Concrete curing and covering

- Temporary waterproofing

- Temporary drainage systems on site

- Dust covers

Damp-proof membranes are typically made of black polythene, for good visibility while building, and a less intrusive final appearance once construction is finished. It is vital that heavy duty polythene is used to reduce the risk of leakage and to maximise protection.

Besides damp-proofing, one of the key uses of black polythene is protecting concrete during curing.

Concrete is highly sensitive to temperature and moisture changes – and extremes can cause poor curing or cracks to develop. This is dangerous in load-bearing structures. Black polythene sheeting is used to cure concrete in specific scenarios where the temperature and moisture need to be controlled during the cure.

Black absorbs light in almost all of the visible spectrum, which is why it looks darker than other colours. But it also absorbs invisible infrared light, too. We humans can’t see infrared – but we can still sense it with our skin, as heat.

In low temperature environments, black polythene sheeting is used to absorb more heat naturally, and to take full advantage of heating lamps in situations that call for it.

Also, covering wet concrete with black polythene sheeting means that moisture can’t escape, and that rain can’t get in. This way, the water content of the mixture can be precisely controlled after pouring. Water reacts with the cement – it doesn’t dry off – so controlling it accurately is important to a strong cure. Concrete that has been tightly temperature and moisture controlled is less prone to cracking or dilution from rainwater.

Polythene for waste disposal

Bin bags were bound to come up at some point. Not all waste is equal, though. Hazardous waste bags (for medical or industrial use) come in a variety of colour coded options. Black polythene waste bags might not be the most glamorous things in the world, but you’d surely miss them if they were gone…

Farming, gardening and agricultural uses

Black polythene is vital to our survival as a species. Hard to believe? Well, consider this; pretty much all the food you eat was grown in black polythene grow bags, in fields irrigated with polythene.

Learn more – Polythene for Agriculture and Farming

Why black? For the same reason black polythene is used for concrete curing; heat. Black absorbs more light, and is naturally hotter than clear or light coloured polythene – so it can be used to warm the soil in frosty seasons, and yield better growth. And, it’s impervious to most wavelengths of light that plants need to survive, which inhibits weed growth.

Black polythene is actually used by gardeners to kill weeds off completely, simply by covering them and robbing them of all sunlight. A black polythene sheet is one of the most effective ways to restart and clear a garden overrun by wild growth – and it even leaves behind a nice mulch layer to feed the next crop.

However: the polythene must use a UV inhibitor as an additive in order to survive exposure to sunlight – otherwise, UV light from the sun will break the polythene down, making it brittle.

Aesthetic uses for black polythene

Black polythene also looks great – and it can be just for looks. It’s useful for branding packaging in company colours, and can make certain print applications pop more vividly (or cut down printing costs for mostly black branding).

Read more – Coloured Polythene: Everything You Need To Know

It can also look less intrusive than other colours in applications like construction or agriculture, where any other colour would stick out and become unsightly.

Order black polythene – the material of a million uses

Order black polythene bags and black polythene sheeting, with any combination of specialist additives for performance-enhancing properties. Let’s help you create the right polythene for your needs; get a quote now, or call us on 01773 820415 to speak to an expert.