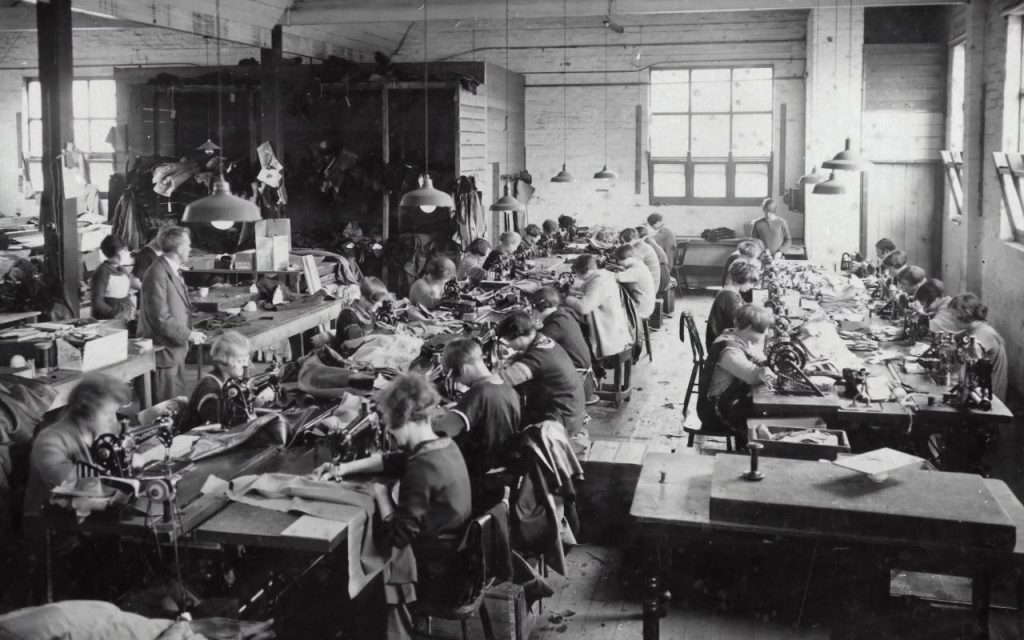

The picture you see below is of a glove factory in England, sometime in the early 1930s. It’s significant because the textile industry was exploding in the country at this time, pulling the country out of the global financial meltdown of 1929. There’s maybe 35 or 40 people pictured working, contributing to the output of hundreds of workers. Together, they could produce thousands of pairs of gloves per week.

The 1930s would mark the end of the boom for the English textile trade. All those people making gloves, coats, hats, scarves, and fine garments – they needed paying. And overseas, lower wages made imports a much more attractive option for consumers.

WWII certainly didn’t help anyone, either… But there was one more nail yet to be hammered into the coffin of British textile manufacturing: automation.

Mass production as a concept was nothing new. The adoption of assembly line techniques and mass production methods had been in force since the industrial revolution. What was new was the rise of automation – machines doing the jobs that until then, only people could do manually.

Overseas investment into automated production, combined with lower labour costs, saw the majority of manufacturing shift eastwards. The knowledge and the skills of manufacturing shifted, too. China, Japan, Bangladesh, India… these nations are now synonymous with manufacturing, catering to a global market in absolutely everything – from the world’s most sophisticated electronics, to bare essential clothing.

Automation changed the world. It shifted global power, and shot the already wealthy into new heights. For a time, the displacement of jobs to automation was a worry. But it also made life better for everyone, and created opportunities for better paid, fairer work.

A transformation in the labour market

Repetitive manual jobs were replaced by machines. And this is what happens when you automate; jobs suffer. That’s always scary and sad for anyone in the firing line. But there are positives to this. Things get faster, cheaper, safer – everything gets better for the vast majority of people. That’s little solace to the factory workers finding themselves without a paycheque – but remember, automation also creates new jobs in the design, maintenance and operation of automated systems. It encourages education and upskilling, and can push people into a better life.

Speaking of which, automation altered society, too. And mostly for the better. Family dynamics, work-life balance and consumer behaviours all shifted; we all, generally speaking, became more prosperous – despite what you may think about rampant consumerism taking over our lives.

Automation gave us our time back. But it also opened our horizons to new, wonderful experiences.

Automated packaging brought the world to our doorstep

Automated packaging is one of the reasons human beings have been able to achieve so much in such little time. Food can be produced anywhere in the world, then be packaged and protected so well that it can arrive fresh. Without automated packaging, that simply couldn’t happen.

It’s given us fizzy drinks and crisps, brand new iPhones delivered intact – it’s given us Amazon warehouses, stocked to the rafters with polythene-wrapped products, ready to be shipped the same day.

We wouldn’t recognise the world we live in without automation. We wouldn’t recognise ourselves. Actually, most of us wouldn’t even have been born.

The role of auto bags in modern packaging

And so, we come to this. One seemingly benign little invention that propelled the human race into global domination. Auto bags – incredibly simple, pre-opened bags on a roll. Auto bags are open on one side, for automated product insertion, and perforated on

the back for automated tear-off.

Learn more about auto bags and automated packaging

The simple rotary action makes designing automated packaging systems much simpler, cheaper, and more accessible to manufacturers. The bags themselves are cost-effective and versatile – offering a brilliant first step into the world of automated (or semi-automated) packaging solutions.

Auto bags have allowed more manufacturers than ever to scale up, and become competitive with household names on both price and quality. While there are more efficient ways to create automated packaging, and they might not be a perfect fit for every product – it’s not a stretch to say that autobags have transformed our lives.

Even if most of us are completely unaware of it.

Auto bags – fast, effective packaging

NPF Packaging is a UK polythene manufacturer. Get auto bags tailor made to your products, and compatible with all major automated packaging systems. Get a quote now, or call us on 01773 820415.