Automated packaging systems are essential at a certain level of production. Nothing is as fast or cost-effective. And even though staff are still needed to oversee the packaging process and pick up what machines can’t, overall dependence on manual labour is greatly reduced.

But there are different grades of automation – ranging from mostly manual, to semi-automated, to fully automated. Even full automation has different levels of completeness and efficiency. An entry-level automated packaging system is likely to make use of auto bags; special polythene bags on a roll that offer continuous item bagging on a production line.

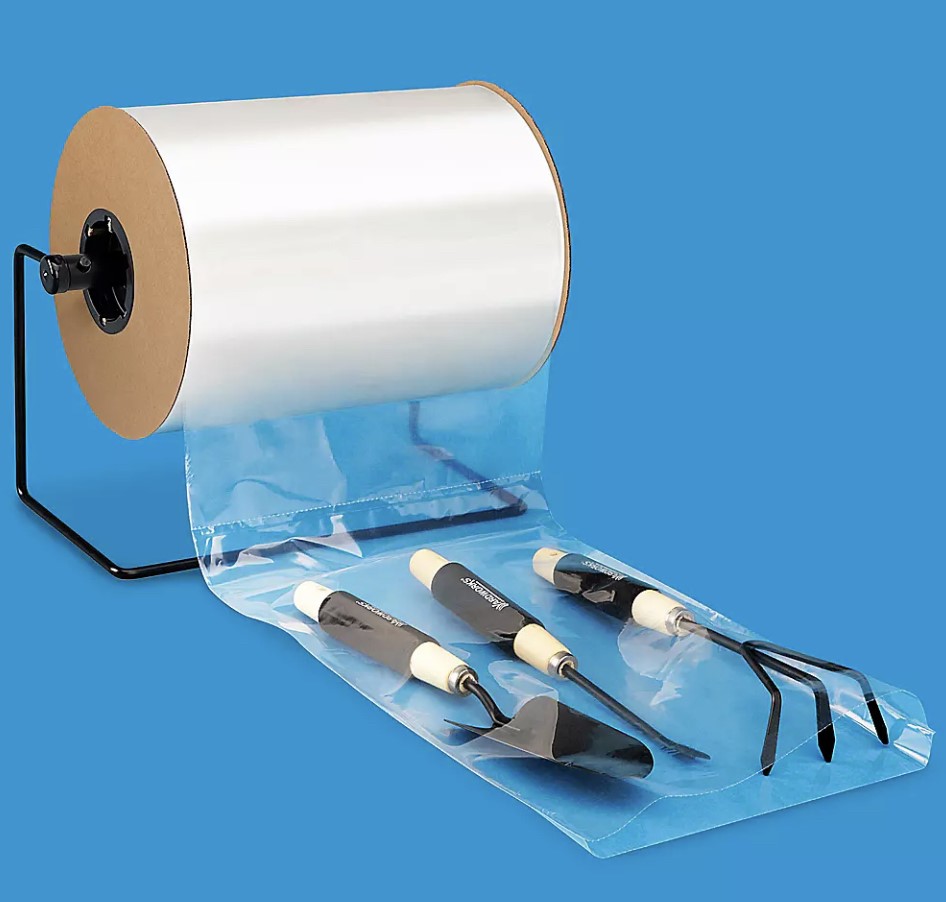

Pre-opened bags on a roll

Autobags are essentially pre opened bags on a roll made to your products’ dimensions. They can be made from coloured polythene, recycled material, and can have gussets added during production for a better fit. They can be printed, too. Being pre-opened makes the production line run quickly and smoothly, with no need for a bag opening mechanism (this is often complex or finicky to set up, and just another thing to go wrong).

An automated packaging machine made to work with auto bags feeds products into each pre-opened bag, then sends it down the line for further additions, or for final sealing and labelling. Using auto bags is super simple, very reliable, and gets a great final result. In fact, loads of the products that you’ve bought and used in your life were packaged in this way – it’s pretty common in many industries.

Advantages of pre-opened bag systems

Probably the biggest advantage of using pre opened auto bags on a roll is simplicity – both of the process and the initial setup. It’s one of the most financially accessible automated packaging systems; an auto bag filler can be bought “off the shelf”, so to speak., and go straight to work with no modification.

Auto bag systems are perfect for successful single product manufacturers; companies who’ve grown beyond manual and semi-automated packaging, but aren’t yet at full-blown industrial level mass production. However, they do have some downsides – and the first one is related to the “off the shelf” nature of auto bag packaging systems.

Disadvantages

The main disadvantage of auto bag packaging systems is that they’re not very flexible. Manufacturers with variable-sized products or different volumes and weights might not be able to get much use out of them, and will have to go for a custom solution off the bat.

Also, there can be a higher cost over time than other packaging systems. While making your own packaging on-demand with an automated, custom built automatic packaging machine will definitely cost more upfront, the cost saving over time more than makes up for it.

Moving on to SWS: making your own bags

The economy of scale allows for deeper investment upfront – and that’s why larger, more established companies choose to create their own packaging on-site, usually from Polythene single wound sheeting (SWS).

Take for example Lego, a product we’re probably all familiar with from childhood or parenthood, which has an infinite number of combinations for sets. All of the Lego elements need to be bagged, and while polythene is not always used (it is for some components), SWS is the format of choice – because, much like Lego itself, it can become anything.

Single wound sheeting can be printed, folded over, gusseted and sealed into bags or packets, as desired. It is far more flexible and affordable than single-size polythene bags at an industrial scale, and it minimises packaging wastage for variable products.

However, the initial investment required for a custom solution like this is pretty major. For all the savings it’ll eventually add up to, a fledgling company likely won;t have the capital to stump up for a custom packaging machine. Even for an established business with a couple of core products of one size, using pre opened bags and auto bags for their packaging lines makes much more sense than going fully bespoke.

Of course, pre opened bags on a roll can be custom made to order – in a range of sizes, with custom polymer blends, colours and printing. All you need is a packaging partner who can do it all for you…

Custom orders for polythene auto bags

Let NPF Packaging design and deliver custom Autobags on a roll. Get a quote online, or call us on 01773 820415.